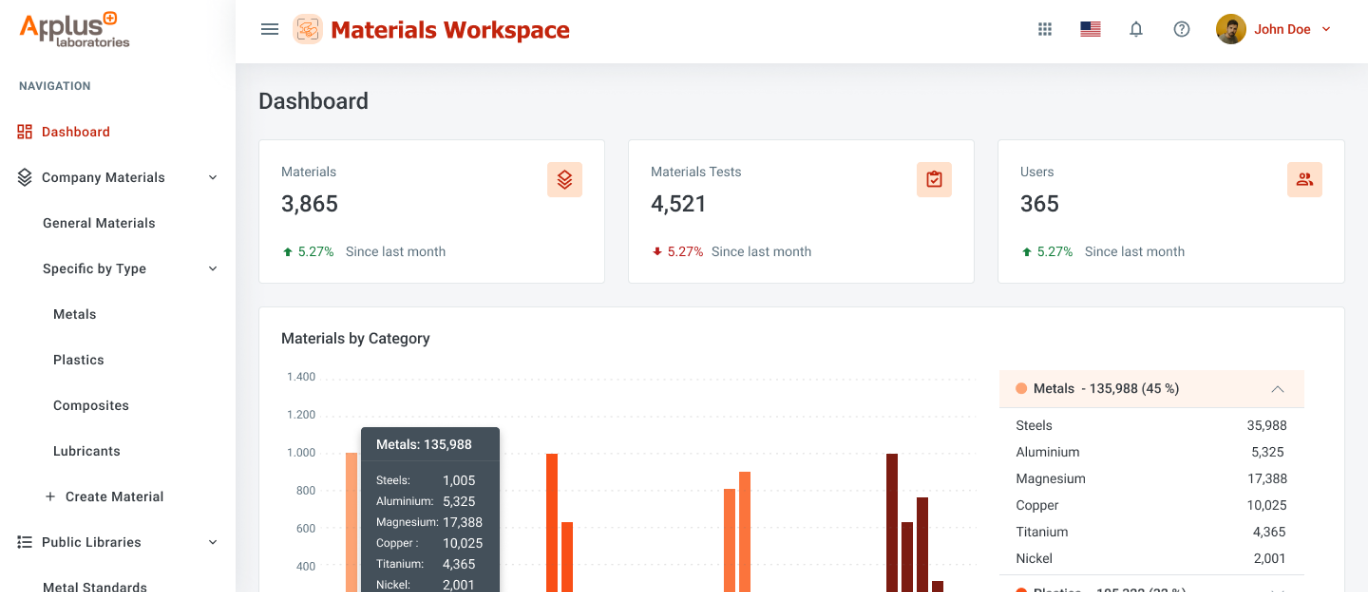

Centralized material data management for precision engineering

Drive the power of released materials data management from one single point of truth

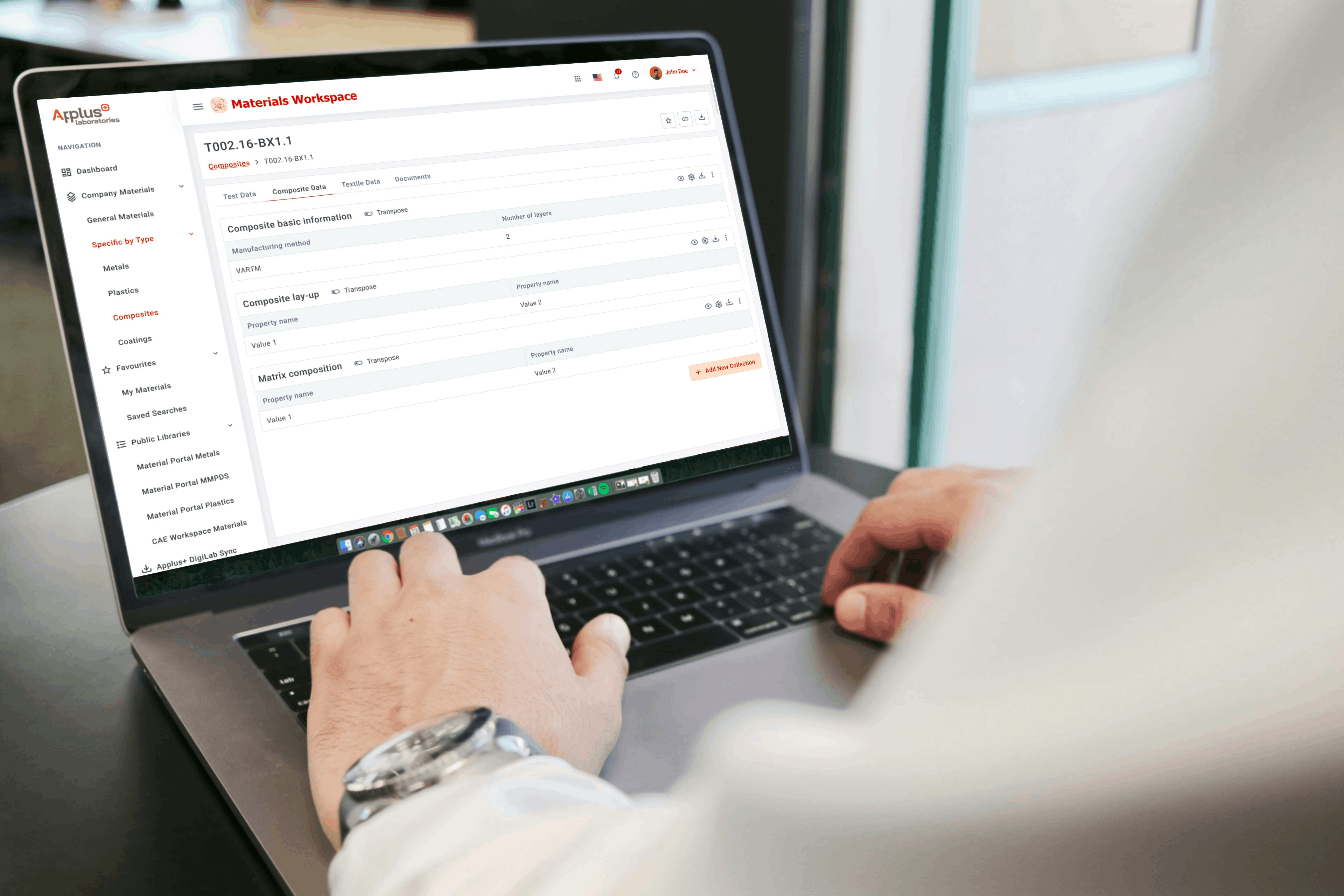

Connected data platform

Material comparison

Search from Materials Portal

Material customization

Real-time updates & notifications

Approval workflows

Estimate materials data with AI

Manage your interfaces

How Materials Workspace stands out

Centralised data access

- Single source of truth for all materials-related data (composition, properties, test results, etc.)

- Eliminates data silos across teams or departments

- Improves collaboration between R&D, engineering, QA, and manufacturing

Improved data security & integrity

- Controlled access and versioning

- Audit trails to track changes

- Reduces errors from using outdated or incorrect materials data

Reduced redundancy & waste

- Avoids duplicate experiments by making past data searchable and reusable

- Reduces material testing costs and time

- Helps optimise resource usage

Faster decision-making

- Enables rapid comparison of materials and alternatives

- Quick access to historical test results and material performance

- Accelerates product development timelines

Scalability & future-proofing

- Adapts to growing datasets and evolving workflows

- Supports cloud-based access and remote work

- Helps organisations transition to data-driven material innovation

Trusted by Industry Leaders

Flexible plans and powerful features for every business

The journey towards digitalising your materials department

Identify where your materials data is stored and how easy it is to access. Many companies scatter data across PDM/PLM systems, ERP platforms, or even individual spreadsheets. For example, engineers might spend hours searching for information across various sources, leading to delays or outdated data being used.

- Map all data storage locations.

- Analyse how long it takes to access critical information.

- Understand how teams access and use this data.

After assessing, identify the gaps. Are there inefficiencies in how information flows? Are materials approvals delayed? If a key expert is unavailable, does it affect decisions or cause delays?

- Highlight bottlenecks in data access.

- Identify manual processes slowing down the team.

- Pinpoint risks, like losing knowledge when employees leave.

Once gaps are identified, implement a digital solution like Material Workspace. It centralises all materials data, offering secure and easy access across the organisation. Imagine how much time you’d save if engineers could access up-to-date data in seconds from a single platform, without needing multiple tools.

- Centralise materials data in one system.

- Streamline workflows and approval processes.

- Ensure all teams access the same data anytime and anywhere.

Digitalising leads to immediate benefits like improved efficiency and transparency. Teams will spend less time searching for data, and material approvals will speed up. For instance, a company could reduce project delays by 30% with a unified data source.

- Faster decision-making through better data access.

- Less duplication of work.

- Clear visibility at every stage of material usage.

In the long run, digitalisation guarantees quality control, traceability, and smoother cross-team collaboration. Material Workspace provides a reliable system for tracking materials throughout the product lifecycle, ensuring compliance and meeting quality standards. Many companies have seen improved collaboration when material data is easily accessible to all departments.

- Better quality assurance with traceable data.

- Smoother interdepartmental collaboration.

- Enhanced compliance with industry standards.